Regarding electrical work, one crucial document that often gets overlooked is the panel schedule.

Table of Contents

What Is a Panel Schedule in Electrical Work?

A panel schedule is a detailed blueprint of a building’s electrical circuits. It lists each circuit, its load, wire, and breaker sizes, and panel locations, helping electricians understand the system layout and identify issues.

Panel schedules are essential for maintaining safety and efficiency. They provide a clear view of all circuits and loads, making troubleshooting faster and easier.

They also serve as a key reference for future upgrades or changes. By showing the current system setup, panel schedules help prevent overloads and support safe, informed modifications.

What Does a Panel Board Schedule Show?

A panel board schedule typically includes the following information:

1. Circuit Number

Each circuit in the panel is assigned a unique number for identification purposes. The circuit number helps electricians and other professionals locate and reference specific circuits within the panel schedule. By organizing circuits numerically, it is easier to track and document the various loads and connections in the electrical system.

2. Load Description

The load description provides details about the type of load connected to each circuit. This could include lighting fixtures, outlets, appliances, or other electrical devices. By accurately describing the loads on each circuit, electricians can quickly identify the purpose of the circuit and determine if any changes or modifications are necessary.

3. Breaker Size

The breaker size indicates the amperage rating of the breaker that protects each circuit. Breakers are designed to trip and disconnect power in the event of an overload or short circuit, preventing damage to wiring and equipment. By specifying the breaker size in the panel schedule, electricians can ensure that each circuit is adequately protected and compliant with safety regulations.

4. Wire Size

The wire size refers to the gauge and type of wire used in each circuit. Proper wire sizing is crucial for maintaining the integrity of the electrical system and preventing overheating or voltage drop. By including the wire size in the panel schedule, electricians can verify that the wiring is adequate for the load and prevent safety hazards associated with undersized conductors.

5. Panel Location

The panel location indicates the position of each circuit within the panelboard. This information helps electricians identify the physical location of circuits and troubleshoot issues more efficiently. By organizing circuits based on their panel location, it is easier to track and maintain the electrical system over time.

Why Panel Schedules Matter in Commercial Electrical Jobs?

In commercial electrical jobs, panel schedules are essential due to the complexity of the systems involved.

1. Regulatory Compliance

Commercial buildings are subject to various regulations and codes governing electrical installations. Panel schedules play a crucial role in demonstrating compliance with these requirements by documenting the layout and specifications of the electrical system. Failure to maintain accurate panel schedules can result in fines, penalties, or legal liability for building owners and contractors.

2. Efficient Maintenance

Commercial properties often have complex electrical systems with multiple panels, circuits, and loads. A well-organized panel schedule can streamline maintenance activities by providing a clear roadmap for inspecting, testing, and servicing electrical components. By following the information in the panel schedule, maintenance personnel can quickly locate and address issues, reducing downtime and minimizing disruptions to business operations.

3. System Integration

Many commercial buildings incorporate advanced technologies and systems that require integration with the electrical infrastructure. Panel schedules help ensure that these systems are correctly connected and powered, preventing compatibility issues and malfunctions. By carefully documenting the connections and loads in the panel schedule, electricians can facilitate the integration of new equipment and technologies without compromising the safety or performance of the electrical system.

4. Risk Management

Effective risk management is essential in commercial electrical jobs to protect against hazards such as electrical fires, equipment failures, and power outages. Panel schedules are a valuable tool for identifying and mitigating risks by providing a detailed overview of the electrical system. By proactively addressing potential issues identified in the panel schedule, contractors can minimize the likelihood of safety incidents and ensure the reliability of the electrical infrastructure.

Types of Electrical Panel Schedules

There are several types of panel schedules used in different electrical systems:

1. Main Panel Schedule

The main panel schedule details the circuits and loads in the primary electrical panel of a building. This document serves as a comprehensive overview of the entire electrical system, identifying the main power source and distribution points. Main panel schedules are essential for understanding the overall electrical layout and capacity of a building.

2. Subpanel Schedule

In buildings with multiple subpanels or distribution boards, each subpanel will have its own schedule. Subpanel schedules provide detailed information about the circuits and loads connected to each subpanel, helping electricians coordinate maintenance and troubleshooting activities. By documenting the subpanel layout and connections, electricians can ensure that power is distributed efficiently and safely throughout the building.

3. Service Entrance Schedule

The service entrance schedule focuses on the circuits connected to the service entrance, where power enters the building from the utility supply. This schedule typically includes information about the main disconnect, metering equipment, and other critical components of the electrical service. Service entrance schedules help electricians verify the integrity of the incoming power supply and ensure proper distribution to the building’s internal circuits.

4. Generator Panel Schedule

In buildings with backup generators or emergency power systems, a generator panel schedule outlines the circuits associated with the generator. This document specifies the connections, loads, and transfer switches necessary to activate the generator during power outages. Generator panel schedules are essential for maintaining the reliability of critical systems and ensuring an uninterrupted power supply in emergencies.

5. Emergency Panel Schedule

For buildings with emergency lighting and power circuits, an emergency panel schedule is used to identify and document these critical systems. Emergency panel schedules outline the circuits connected to emergency generators, batteries, and backup power sources, ensuring that essential loads are powered during outages. By clearly labeling and organizing emergency circuits, electricians can prioritize maintenance and testing to guarantee the functionality of emergency systems.

6. Specialized Panel Schedules

In addition to the standard panel schedules mentioned above, there are specialized panel schedules for specific applications or industries. For example, industrial facilities may have motor control center schedules that detail the circuits and controls for motors and machinery. Likewise, data centers may utilize IT equipment schedules to document the power distribution and backup systems for servers and networking gear. These specialized panel schedules cater to the unique requirements of certain installations, providing a tailored approach to managing electrical systems.

7. Smart Panel Schedules

With the rise of smart technology and automation in buildings, smart panel schedules have emerged as a way to monitor and control electrical systems remotely. Smart panel schedules integrate with building management systems to provide real-time data on energy consumption, equipment status, and power quality. By leveraging smart panel schedules, facility managers can optimize energy usage, detect faults early, and improve overall system performance.

What Information Is Included in an Electrical Panel Schedule?

When creating an electrical panel schedule, it is essential to include the following information:

1. Panel ID

The panel ID is a unique identifier for the electrical panel and helps distinguish it from other panels in the building. Each panel should have a distinct ID for reference and documentation purposes. Panel IDs are typically alphanumeric codes or labels that correspond to specific locations or functions within the electrical system.

2. Circuit Number

Assigning a sequential circuit number to each circuit in the panel allows for easy identification and organization. Circuit numbers help electricians trace wires, troubleshoot problems, and record changes accurately. By following a consistent numbering system, users can maintain order and clarity in the panel schedule, reducing confusion and errors.

3. Load Description

Describing the load on each circuit provides essential information about the type of equipment or devices connected to the circuit. Load descriptions can include details such as lighting fixtures, receptacles, appliances, motors, or specialized equipment. By documenting the load description, users can understand the purpose of each circuit and determine its electrical requirements.

4. Breaker Size

The breaker size indicates the amperage rating of the circuit breaker that protects the circuit from overcurrents. Breaker sizes are crucial for ensuring that the wiring and equipment connected to the circuit are adequately protected. By specifying the breaker size in the panel schedule, users can adhere to safety regulations and prevent electrical faults that could lead to damage or injury.

5. Wire Size

Documenting the wire size used in each circuit helps verify that the wiring can safely carry the electrical load without overheating or voltage drop. Wire sizes are determined based on the current rating of the circuit and the distance the wire must travel. By including the wire size in the panel schedule, users can confirm that the wiring meets the requirements of the electrical code and is suitable for the intended application.

6. Location

Identifying the physical location of each circuit within the panelboard is essential for maintenance, troubleshooting, and installation purposes. The location information helps electricians locate specific circuits quickly and accurately. By noting the position of each circuit in the panel schedule, users can coordinate work efficiently and minimize errors during electrical tasks.

How to Make a Panel Schedule

Creating a panel schedule requires careful planning and attention to detail. Here are the steps involved:

1. Gather Information

Start by collecting all necessary details about the electrical system, including circuit loads, breaker sizes, wire types, and panel locations. Consult wiring diagrams, equipment specifications, and building plans to ensure accuracy.

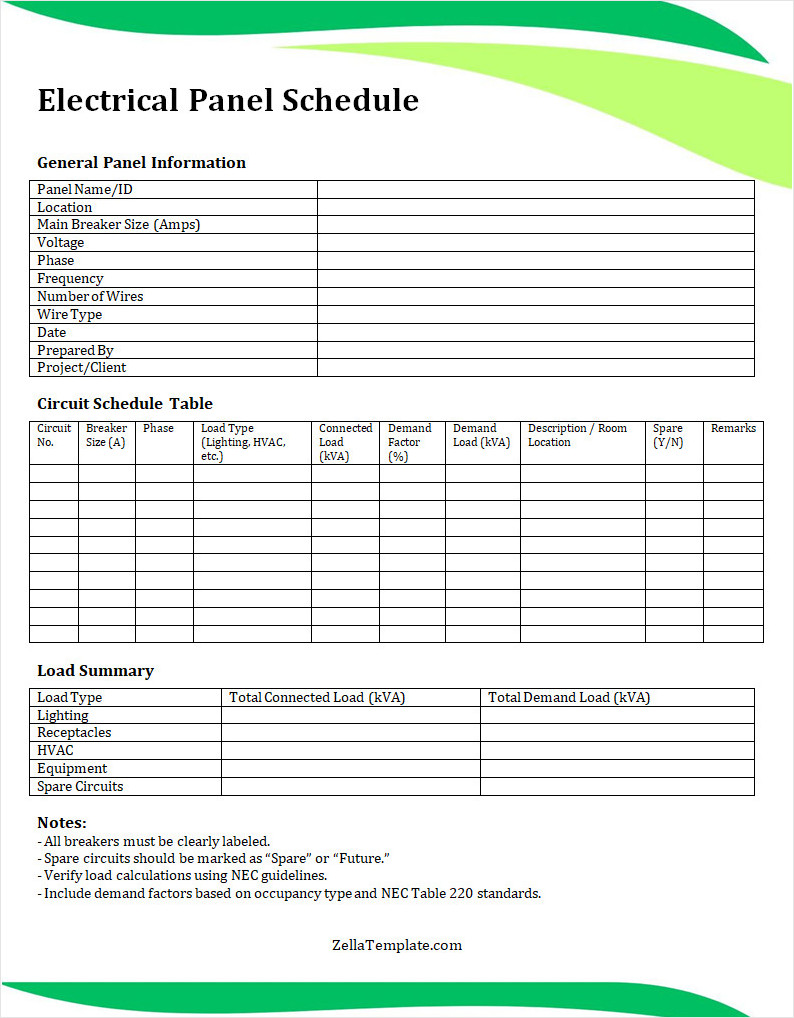

2. Create a Template

Design a standardized template for the panel schedule that includes fields for panel ID, circuit number, load description, breaker size, wire size, and location. Use software tools or spreadsheet programs to create a digital template for easy editing and sharing.

3. Fill in the Details

Input the gathered information into the panel schedule template, making sure to include all required details for each circuit. Double-check the accuracy of the data and cross-reference with equipment labels or manuals as needed.

4. Review and Verify

Review the completed panel schedule for errors, omissions, or inconsistencies. Verify that the information aligns with the actual electrical system and matches any documentation provided by manufacturers or designers.

5. Update as Needed

Regularly update the panel schedule whenever changes are made to the electrical system, such as adding new circuits, upgrading equipment, or relocating panels. Keep a revision history to track modifications and ensure the schedule remains current.

Common Mistakes to Avoid in Panel Scheduling

When creating a panel schedule, it is important to avoid the following common mistakes:

1. Missing Information

Failing to include crucial details such as wire sizes or breaker sizes can lead to confusion and errors during maintenance or troubleshooting. Ensure all relevant information is accurately documented in the panel schedule.

2. Disorganized Layout

A cluttered or disorganized panel schedule can make it challenging to read and interpret, resulting in inefficiencies and mistakes. Arrange the information in a logical and structured format for easy reference and understanding.

3. Incorrect Labeling

Using incorrect circuit numbers or load descriptions can cause confusion and delays when working on the electrical system. Verify all labels and identifiers to ensure they match the actual components and connections in the panel.

4. Outdated Information

Failure to update the panel schedule with changes to the electrical system can lead to inaccuracies and safety hazards. Regularly review and revise the schedule to reflect any modifications or additions made to the system.

5. Lack of Documentation

Not keeping a record of previous versions or revisions of the panel schedule can complicate future maintenance or modifications. Maintain a comprehensive record of all changes and updates to the schedule for reference and compliance purposes.

Electrical Panel Schedule Template

Start using our free electrical panel schedule template today to organize circuit information, ensure safety, and streamline your electrical planning process.

Electrical Panel Schedule Template – Word