What is a Temperature Log Sheet?

A temperature log sheet is vital for recording and monitoring temperature readings across industries. It ensures products like food, pharmaceuticals, and chemicals are safely stored. Logs may be kept manually or digitally with automated systems. Accurate logs help businesses meet regulations, detect issues, and protect product integrity.

Table of Contents

Why’s It Important?

1. Ensuring Product Safety and Quality

Temperature log sheets are important to ensure the safety and quality of temperature-sensitive products. Perishable foods require specific temperatures to prevent spoilage. Failure to maintain correct conditions can cause foodborne illness, product recalls, or financial losses for businesses.

2. Preventing Spoilage and Waste

Temperature log sheets help businesses prevent spoilage, waste, and losses by alerting them to temperature deviations threatening product integrity. Pharmaceutical products may lose potency if exposed to heat, making them unsafe. Promptly addressing issues minimizes losses and ensures products remain safe for use.

3. Compliance with Regulations

Health and safety regulations require businesses handling temperature-sensitive items to maintain proper controls and monitoring. Temperature log sheets document compliance, showing precautions to protect product safety and integrity. Failure to follow requirements can lead to fines, penalties, or legal consequences.

4. Demonstrating Due Diligence

During inspections, audits, or disputes, temperature log sheets demonstrate business due diligence. Consistent records and corrective actions prove efforts to ensure product safety and quality. This documentation is invaluable for defending against negligence or misconduct claims.

When Do You Need a Temperature Log Sheet?

Businesses that handle temperature-sensitive items must use temperature log sheets to monitor and document temperature conditions effectively. Knowing when to implement temperature log sheets can help businesses maintain product integrity, comply with regulations, and uphold consumer safety.

1. Food Service Industry

In the food service industry, temperature log sheets are essential for monitoring the storage and handling of perishable food items. Restaurants, catering services, food trucks, and other food establishments must maintain proper temperature controls to prevent foodborne illnesses and ensure food safety. Temperature log sheets help food service businesses comply with food safety regulations, conduct hazard analysis, and maintain quality assurance standards.

2. Healthcare Facilities

Healthcare facilities such as hospitals, clinics, pharmacies, and laboratories rely on temperature log sheets to monitor the storage of vaccines, medications, blood products, and other temperature-sensitive medical supplies. Proper temperature management is critical to preserving the efficacy and safety of medical products and preventing adverse patient outcomes. Temperature log sheets are essential for healthcare facilities to comply with regulatory requirements, accreditation standards, and best practices in medication management.

3. Retail Stores

Retail stores that sell temperature-sensitive items like dairy products, frozen foods, cosmetics, or floral arrangements can benefit from using temperature log sheets to ensure product quality and safety. Monitoring the temperature conditions in refrigerated display cases, cold storage areas, or climate-controlled environments is essential to prevent product spoilage, maintain freshness, and uphold customer satisfaction. Temperature log sheets help retail stores uphold product integrity, comply with industry standards, and mitigate risks associated with temperature fluctuations.

4. Research Laboratories

Research laboratories involved in scientific experiments, pharmaceutical development, or biological studies rely on temperature log sheets to monitor environmental conditions and ensure the integrity of research materials. Maintaining precise temperature controls is crucial for protecting valuable samples, reagents, and equipment from damage or degradation. Temperature log sheets assist research laboratories in maintaining data integrity, conducting reproducible experiments, and complying with regulatory guidelines for laboratory operations.

How Often To Check Temps

The frequency of temperature checks depends on various factors, including the type of temperature-sensitive items being stored, the storage conditions, regulatory requirements, and best practices in temperature monitoring.

Establishing a regular schedule for checking temperatures helps businesses maintain consistent quality standards, prevent product losses, and ensure compliance with relevant guidelines.

How To Use a Temperature Log Sheet?

Effectively using a temperature log sheet involves following systematic procedures, maintaining accuracy, and ensuring consistency in temperature monitoring practices. By adopting best practices in temperature logging, businesses can enhance product safety, quality assurance, and regulatory compliance.

Here are some key steps for using a temperature log sheet effectively:

1. Establish Clear Procedures

Before using a temperature log sheet, businesses should establish clear procedures for temperature monitoring, recording, and documentation. Define who is responsible for taking temperature readings, how often readings should be taken, where readings should be recorded, and what actions to take in case of temperature deviations. Providing clear guidelines ensures that temperature monitoring is conducted consistently and accurately.

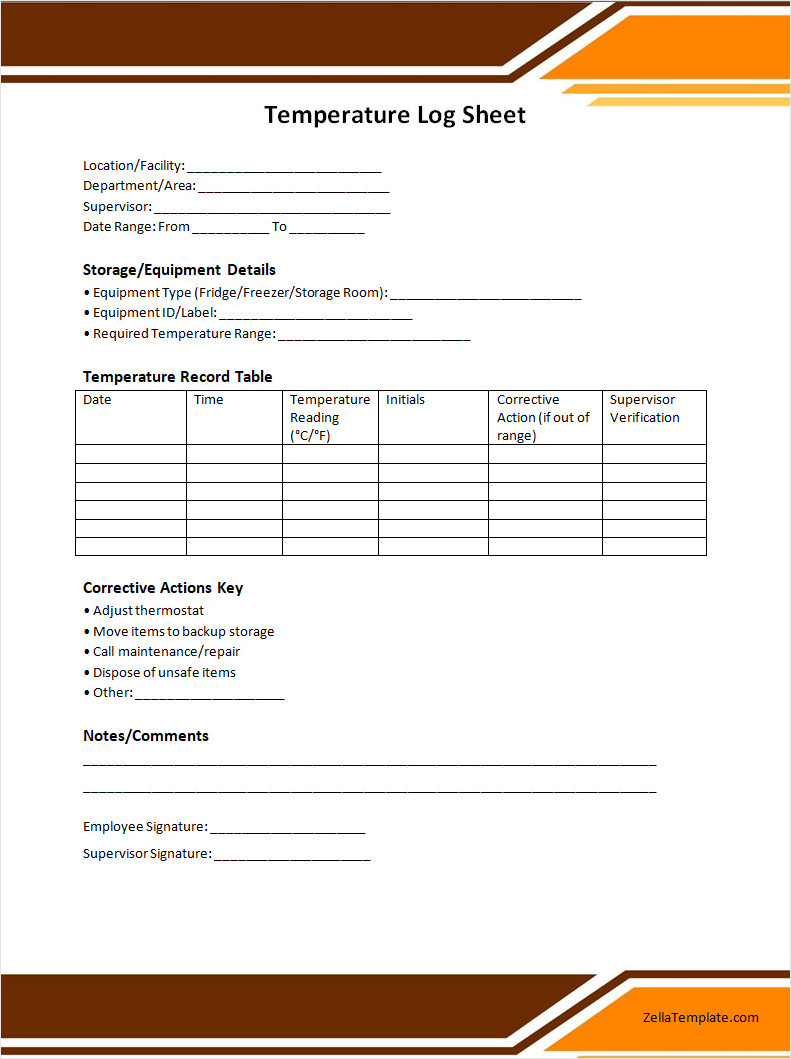

2. Use Standardized Formats

Standardizing the format of temperature log sheets ensures uniformity in recording temperature data and facilitates easy interpretation of the information. Use standardized templates with predefined fields for date, time, location, temperature readings, initials, and any additional details required for specific monitoring purposes. Consistent formatting helps streamline data entry, analysis, and reporting processes.

3. Train Personnel

Train personnel responsible for temperature monitoring on the proper techniques for taking accurate temperature readings, recording data correctly, and following established procedures. Provide training on temperature measurement devices, calibration methods, temperature ranges for different products, and the importance of timely and thorough temperature monitoring. Well-trained staff are essential for maintaining data integrity and ensuring compliance with temperature monitoring protocols.

4. Regular Monitoring

Conduct regular temperature monitoring at designated intervals according to your established monitoring schedule. Ensure that temperature readings are taken consistently and at the specified locations to capture accurate data on temperature conditions. Monitor trends, patterns, and deviations in temperature readings to identify potential issues or areas for improvement in temperature management practices.

5. Document Temperature Data

Accurately document temperature readings on the temperature log sheet, including the date, time, location, and actual temperature recorded. Sign or initial the temperature log sheet to verify that the readings were taken as documented. Include any relevant notes or observations related to temperature fluctuations, equipment malfunctions, or corrective actions taken in response to temperature deviations.

6. Review and Analyze Data

Regularly review and analyze the temperature data recorded on the log sheet to identify trends, patterns, or anomalies that may require further investigation. Look for recurring issues, sudden temperature spikes or drops, or any abnormalities in temperature readings that could indicate problems with storage conditions or equipment. Use the data to make informed decisions, implement corrective actions, and improve temperature management practices.

7. Take Corrective Actions

If temperature deviations are detected or if the temperature readings fall outside the acceptable range, take immediate corrective actions to address the issue. Investigate the root cause of the temperature deviation, adjust temperature controls as needed, repair malfunctioning equipment, or transfer temperature-sensitive items to alternative storage facilities. Document any corrective actions taken on the temperature log sheet to demonstrate compliance with temperature management protocols.

8. Maintain Records

Keep detailed records of temperature log sheets, including historical temperature data, corrective actions taken, calibration records, and any relevant documentation related to temperature monitoring practices. Maintain records in a secure and accessible location for future reference, audits, or regulatory inspections. Retain temperature log sheets for the required retention period specified by regulatory guidelines or internal policies.

10. Continuous Improvement

Continuously evaluate and improve temperature monitoring practices based on the analysis of temperature data, feedback from staff, and observations of temperature control processes. Implement feedback mechanisms, conduct regular audits of temperature monitoring procedures, and seek opportunities to enhance temperature management protocols. By striving for continuous improvement, businesses can optimize temperature control measures, reduce risks, and ensure the safety and quality of temperature-sensitive items.

Temperature Log Template – Word